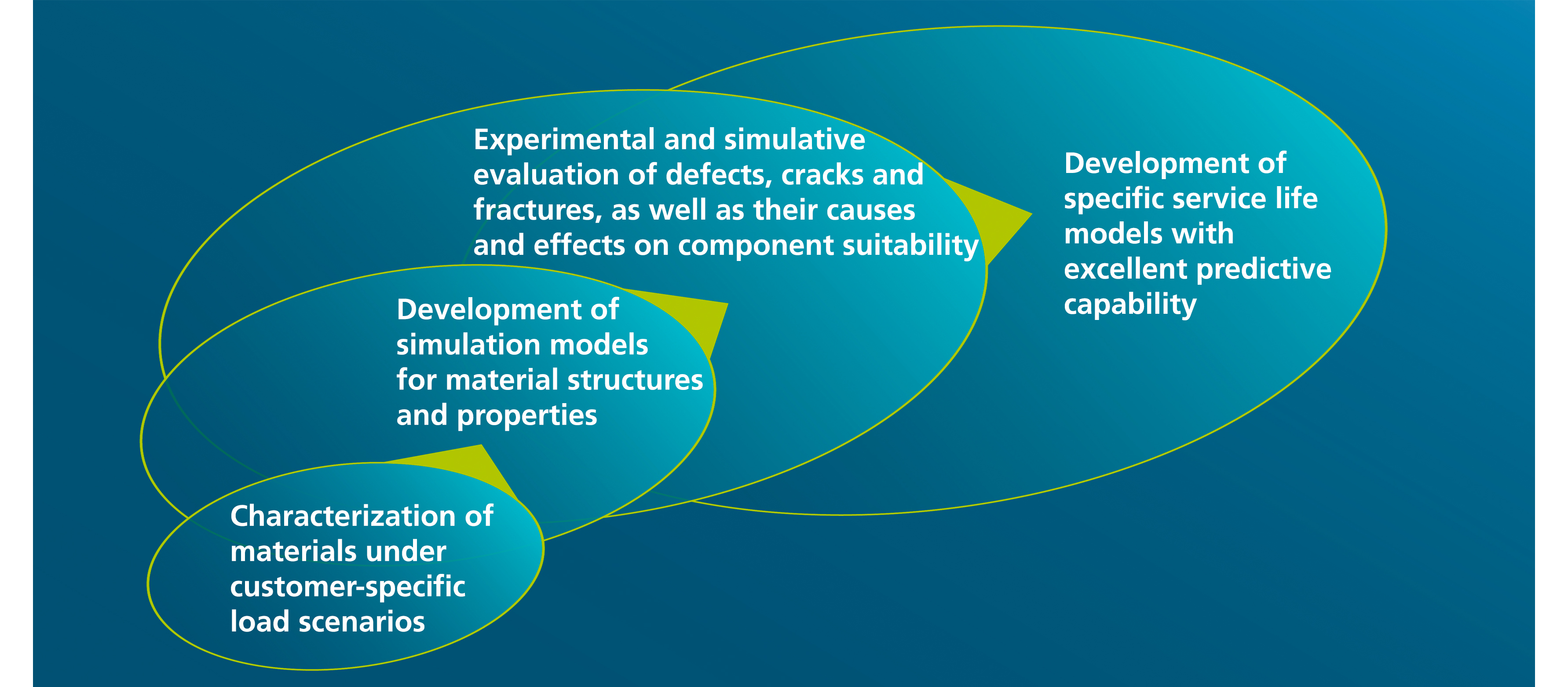

Our contribution to your company ranges from the characterization of materials, consultation and support during decision-making processes to the joint development of new products.

We have a wide range of testing equipment for the characterization of materials using standardized and individual test methods.

We have over 50 years of experience in the interpretation of physically based material behavior in application-specific contexts by means of experimental and simulative investigations.

We ensure that the influence of microstructure, process routes, residual stresses and damage on the functionality and service life of components can be described and understood so that you can make the best possible use of the strength reserves of your construction materials under extreme loads.

Cooperation with the Fraunhofer IWM

You are faced with a materials engineering challenge and need a specific solution. We support you in finding and implementing that solution. Research projects begin with a non-binding consultation. Here, we explore which goals can be achieved and what the time and financial framework might look like. The highest level of professionalism in project processing is independent of the size of the project.

Some tasks are more complex and interdisciplinary, so that the expertise of several Fraunhofer Institutes is required for the solution. In such cases, we have experience in the efficient and transparent handling of large projects involving several Fraunhofer Institutes. And we know which funding options are available.

With publicly funded research projects - from the state, federal government or EU - industrial companies develop new topics together with research institutes.

Industrial partners and research institutes jointly apply for funding for a joint project. The results of such projects are pre-competitive findings and widely applicable methods. These for example can be adapted and transferred to company-specific requirements and applications as part of contract research.

The Fraunhofer IWM acts as an accelerator in development and innovation processes. A strategic partnership gives you regulated access to our growing expertise and technical capabilities. This provides you with planning security for your research and innovation projects.

to top

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM