Thermophysical and thermomechanical characterization

Everything from a single source - contact us!

- We have a wealth of experience in the field of thermophysical measurements

- We are always at the forefront of the latest developments

- We are in constant dialogue with science and industry thanks to our diverse collaborations

- We carry out reliable measurements in accordance with standards or design customized solutions for your problem

- We have an interdisciplinary team - experiment and simulation go hand in hand

- If required, we can carry out a supplementary microstructure analysis or create a material model for your material

- We manufacture your samples in our in-house workshop

- We support you with our expertise in the implementation of the results

Thermophysical characterization

The modern equipment and procedures in the Fraunhofer IWM thermophysical and thermomechanical labs enable us to determine temperature dependent material properties. These properties provide the essential basis for evaluating the effects of thermal loads on components. This substantiated data is necessary for FE- simulation in order to optimize production processes, contour accuracy and energy usage. We determine the following parameters:

- Heat capacity

- Thermal expansion

- Thermal Diffusivity

- Heat conductivity

- Melting point / Solidus and Liquidus temperature

- Phase transformation

- Softening point (for example, glass Transition)

- Magnetic transformation

- Latent heat / reaction enthalpy

- Shrinkage (for example, during the sintering process)

Contact us! Together we'll find a customized solution for the challenges you face.

How to work with the Fraunhofer IWM

Thermomechanical material testing

- Combined tensile and compression testing (also at high temperatures and velocity)

- TTT diagrams (Time-Temperature-Transformation)

- Welding simulations and replication of heat treatment and quenching processes

- Thermomechanical material treatments for virtually all loads and/or temperatures

Our approach to material testing enables simulation and interpretation of production processes, more detailed damage analysis, the development and qualification of new alloys and the optimization of material combinations. Our clients often need us to answer the following questions:

- What influence does temperature have upon component geometry?

- What is the heat conductivity of a given material?

- In which ways does a thermal production process alter a component's shape?

- What is the optimal heat treatment for a component that warps?

- How to avoid warpage by welding?

- Specifically for glass and polymer: how high is the glass transition temperature?

The thermophysical and thermomechanical material characterization that we offer is of specific benefit to manufacturers who work with metals, ceramics, synthetic materials, polymers and glass, as well as for process steps which include shaping, heat treatments, welding, warm forming and cold forming.

Our measurement results provide the reliable data necessary for simulations and help clients to optimize their processes while minimizing energy requirements.

Contact us! Together we'll find a customized solution for the challenges you face.

How to work with the Fraunhofer IWM

Thermophysical characterization - details

Specific heat capacity using Differential Scanning Calorimetry (DSC)

- Measurements from room temperature (RT) to 1600 °C with heat rates between 0.01 to 50 K/min

- Determination of melting and transformation temperatures

- Quantitative determination of exothermal and endothermal reactions

- Measurements in various gas atmospheres and in vacuum

- Typical specimen sizes of solids: Ø 5x0.5 mm

Differential Scanning Calorimeter (DSC)

- Temperature range from room temperature (RT) to 1650 °C

- Cp measurements from room temperature (RT) to 1500 °C

- Vacuum 10-4 mbar

DSC measuring principle

A sample pan and a reference pan are placed on a platinum disk. When the furnace is heated, both pans consume energy and heat up, but the heat flow from each pan into its platinum disk takes place at different rates. This heat flow difference is measured by thermocouples in a differential set-up. Changes in the DSC signal allow for the analysis of the heat capacity as well as melting, phase transformations, evaporation, and other reactions within the material.

Application examples DSC

The enthalpy changes of exothermic and endothermic processes during the heating and cooling of a low-carbon steel can be determined on the basis of a change in the measured heat flow.

Thermal expansion using thermomechanical analysis (TMA)

- Measurements from room temperature (RT) to 1550 °C with heat rates between 0.1 und 50 K/min

- Determination of thermal expansion coefficient and phase transformations

- Measurements in various gas atmospheres and in vacuum

- Typical specimen sizes: Ø 4-6 mm, 5-25 mm length; similar specimen sizes for sheet materials

Thermomechanical Analyzer (TMA)

- Temperature range from room temperature (RT) to 1550 °C

- Maximum specimen length 30 mm

- Measuring range ± 2.5 mm

- Force range 0.001 N to ± 3 N

- Vacuum < 10-4 mbar

- Specimen holder system constructed of Al2O3

TMA measuring principles

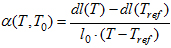

When using a thermomechanical analyzer, a specimen is attached to a rod and clamped with one end in a conductive displacement transducer. With this set up, changes in length can be measured while the specimen is heated in the surrounding oven. From the temperature dependent change in length Δl(T), the technical coefficient of linear expansion α is calculated:

Additionally, volumetric phase transformation, shrinkage and sinter processes can all be measured in the TMA.

Application examples TMA

The direction-dependent thermomechanical analysis shows a significant increase in thermal elongation in the thickness direction compared to the fiber direction for various glass fiber-reinforced polyamides.

Thermal diffusivity and heat conductivity using Laser Flash Analysis (LFA)

- Thermal diffusivity measurements ranging from 0.01 to 1000 mm2/s and from room temperature (RT) to 2000 °C with heating rates from 0.1 to 50 K/min

- Measurements in various gas atmospheres and in vacuum

- Measurements of round specimens with diameters of 6 mm, 10 mm or 12.6 mm; square specimens 10x10 mm

- Specimen thickness is dependent upon expected heat conductivity

Laser Flash Apparatus (LFA)

- Temperature range: room temperature (RT) to 2000 °C

- Laser power 25 J/Puls (adjustable power and pulse duration)

- Contactless measurement of temperature increase with IR Detector

- Measurement range: 0.01 mm2/s to 1000 mm2/s (thermal diffusivity) corresponding measurement range: 0.1 W/mK to 2000 W/mK (thermal conductivity)

- Specimen dimensions: Ø 6 mm to 12.6 mm or square 10x10 mm

- Specimen holder: Al2O3, graphite

- Atmosphere: Ar dynamic

- High vacuum tight up to 10-5 mbar

LFA measurement principles

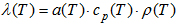

This measuring technique uses a laser as a heat source. The front of the sample is heated by a short laser pulse, and the heat is conducted through the specimen. An infrared detector measures the temperature increase as a function of time on the specimen’s backside. From this temperature profile and the specimen’s size the thermal diffusivity a(T) is computed. The heat conductivity of the sample material can be determined by using temperature dependent density from DIL and thermal capacity from DSC:

Application examples LFA

Laser flash analysis can be used to show the increase in thermal conductivity in an aged aluminum alloy; in comparison to the solution-annealed T6 state, this can be quantified.

Thermomechanical material testing - details

Thermomechanical testing of metal materials using the "Gleeble 3150"

- Heating rate to 8000 K/s and max. cooling rate up to approximately 2500 K/s

- Loading at force and stroke control

- Measurements possible in various gas atmospheres and in vacuum

- Thermomechanical material treatment at various temperature cycles with or without superimposed tensile or compression loads

- Replication of heat treatment processes including quenching processes

- Determination of TTT (Time Temperature Transformation) diagrams

- Determination of TTA (Time Temperature Austenitising) diagrams

- Replication and simulation of specific microstructures

- Determiniation of static, dynamic, mechanical and thermomechanical behavior of heat treated specimens

Additional services

- Specimen manufacturing in the Fraunhofer IWM workshop

- Microstrucural analysis with light microscope or Scanning Electron Microscope (SEM)

- Microstructure evaluation in the Fraunhofer IWM metallography

- Hardness measurements (single indents or hardness distribution)

- Chemical analysis using the glow discharge optical emission spectrometer (GDOES) with depth profiling

- Volumetric phase analysis using X-Ray diffractometry

- Residual stress analysis using an x-ray diffractometry or the hole drilling method

- High resolution phase, texture, precipitation and surface analysis using SEM, EDX and EBSD

- Testing of thermal shock behavior for metals, ceramics and glass

- Measurements of hydrogen content in metals

- Deliberate controlled loading of metal material with hydrogen and determination of hydrogen diffusion constants

- Numerical simulations of the effects of forming processes on components

- Numerical simulations of component behavior under thermal and mechanical loads

Contact us! Together we'll find a customized solution for the challenges you face.

How to work with the Fraunhofer IWM

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM