Design and development of metamaterials and unit cells

The material behavior that is made possible via this method is: targeted shape change under external load (e.g. for adaptable surfaces), control of fluid damping (especially depending on temperature and speed), switchable stiffness (e.g. for soft robotics, orthoses) and adjustable wettability (self-cleaning surfaces).

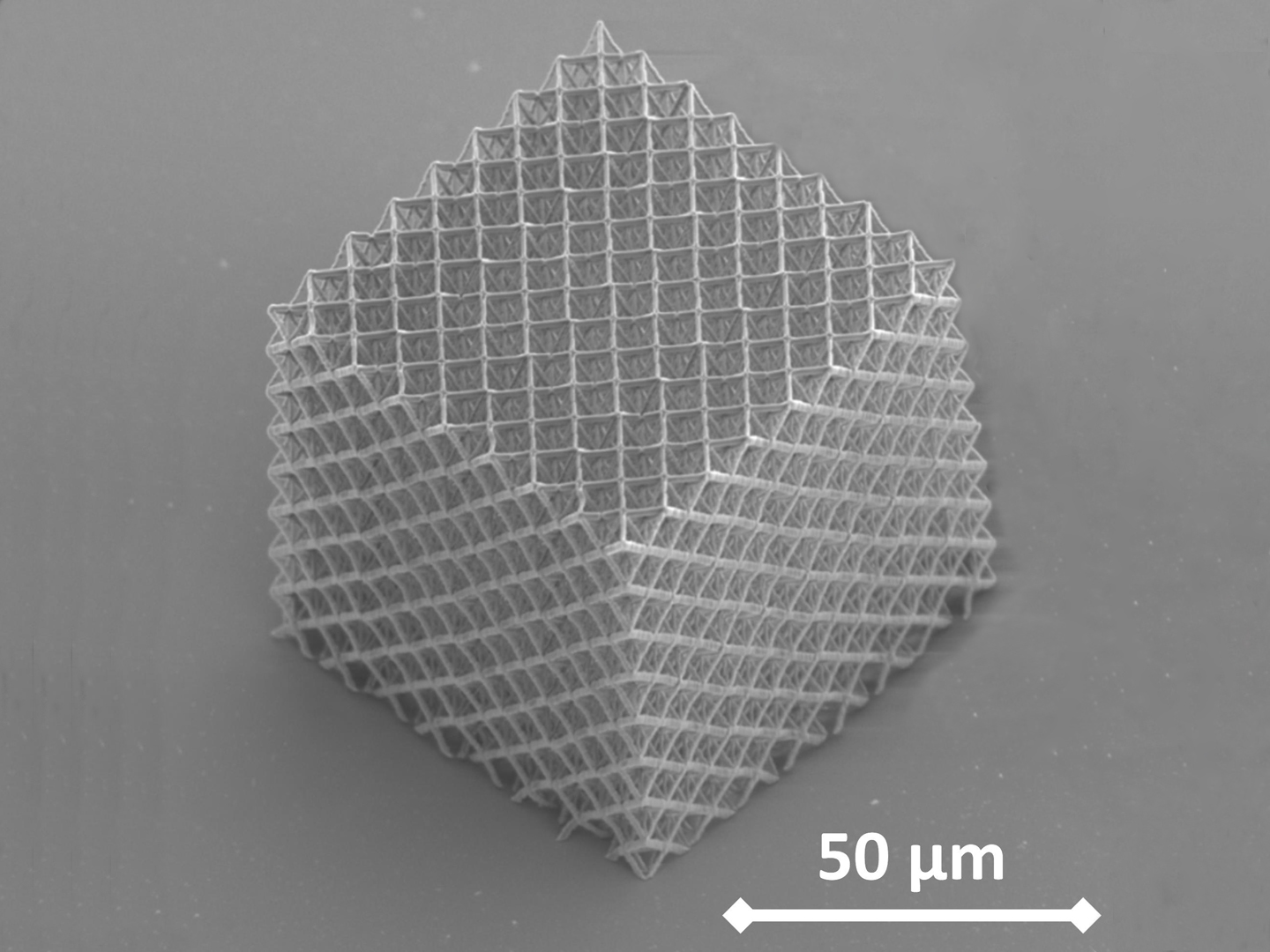

In Materials Design, local and global effects can be incorporated through a hierarchical structure of unit cells. For this purpose, we develop unit cells and arrays in which mechanical mechanisms (contact, rotation, bumps, fluid friction...) are incorporated. These can consist of a mono-material (e.g. PLA or TPU) or several base materials. The former is particularly advantageous in terms of sustainability, the latter allows us to incorporate functional materials and control responsive behavior with triggers such as temperature (see video 1), speed or magnetic field or to use effects of smart materials such as shape memory polymers. Furthermore, symmetries and the targeted incorporation of anisotropies in beam or shell structures can lead to unusual properties. Here, instabilities (targeted buckling or kinking) can be exploited, for example, to generate history-dependent behavior (storage of deformations). The finished unit cells can perform non-linear or linear functions (e.g. transverse strain as a function of the strain rate) and fulfill conditional conditions (if-then). Ideally, these can be combined like functions in an algorithm.

to top

Fraunhofer Institute for Mechanics of Materials IWM

Fraunhofer Institute for Mechanics of Materials IWM